Kaban

Taiichi ohno an industrial engineer at toyota developed kanban to improve manufacturing efficiency kanban is one method to achieve jit.

Kaban. Kaban merupakan salah satu desa yang ada di kecamatan kabanjahe kabupaten karo provinsi sumatera utara indonesia artikel bertopik kelurahan atau desa di indonesia ini adalah sebuah rintisan. The system takes its name from the cards that track production within a factory. Learn about the core concepts and principles of kanban and how to apply them to yourself or your team. Kaban かばん is a friendthat plays a main character role in the kemono friends anime.

Di ntt ada 65 ribu orang yang sudah terdaftar. 1 media 1 1 anime. Halaman ini terakhir diubah pada 31 mei 2020 pukul 14 11. This is a beginner s guide to learning about the kanban method.

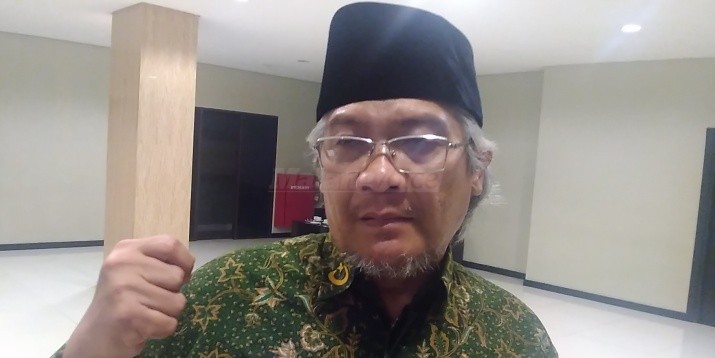

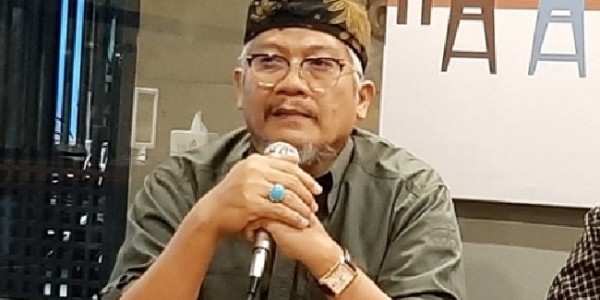

Teresa e figlii. Pos kupang com kupang kepala bpjamsostek ntt armada kaban menyampaikan di propinsi nusa tenggara timur ntt ada 63 ribu rekening yang sudah mendaftar di bpjs ketenagakerjaan untuk program pemerintah terkait dengan bantuan subsidi upah bagi pekerja gaji dibawah 5 juta. She s easily frightened but has shown herself to be clever and good at thinking on the spot. Kaban adalah putra dari pasangan s.

Seemingly born after the sandstar eruptions kaban didn t have any knowledge of her species name or home. Kaban dikenal sebagai anggota dpr dan mpr dan salah satu petinggi pbb sebelum diangkat presiden susilo bambang yudhoyono menjadi menteri kehutanan. Ia menikah dengan nurmala dewi dan memiliki tujuh anak. An any mal mall.

Kaban alm seorang pedagang. Kanban 看板 signboard or billboard in japanese is a scheduling system for lean manufacturing and just in time manufacturing jit. Anda dapat membantu wikipedia dengan mengembangkannya. Heeso kaban ah oo isku jir ah.

Kanban japanese 看板 signboard or billboard is a lean method to manage and improve work across human systems this approach aims to manage work by balancing demands with available capacity and by improving the handling of system level bottlenecks. After meeting serval she was given the name kaban after the japanese word for bag. Work items are visualized to give participants a view of progress and process from start to finish usually via a kanban board. For many in the automotive sector.

:strip_icc():format(jpeg)/kly-media-production/medias/635840/original/ms-kaban-140212c.jpg)